"One man's trash is another man's treasure." This applies to Dustin and me. Whenever anything breaks, he grabs it: coffee makers, vacuum cleaners, telephones, televisions, alarm clocks, electric shavers, computers, it doesn't matter what it is, he wants it. He carefully dismantles the prize looking for useful pieces to build robots. The components are extracted and reassembled into electrical experiments.

When it became impossible to walk through the basement, he decided to do something.

I see trash, he sees treasures.

Others are soldered directly into the circuit board and must be removed by using a solder pot. It's a dangerous process and not something to be performed inside the house.

Dustin works outside with a fan behind his back that blows the toxic fumes safely away.

Scooter checks to make sure all safety precautions are being observed.

He also inspects all tools and verifies they are up to codes. He is the first one to evacuate when the noxious fumes begin wafting across the porch.

A solder pot is a heated bowl full of melted solder which is EXTREMELY HOT and must be used carefully. Slag is floating on the top.

A bar of solder is used to perform the initial filling of the pot. Additional portions of the bar are added periodically to keep it at the desired level. One of the most popular types of solder contains 60% tin and 40% lead. It is purchased over the internet and arrives in the mail in solid form.

The circuit boards are placed on top of the solder pot. The molten solder contacts the component legs on the underside and melts the connectors away. Components are the building blocks of circuits which are put together to build useful things, process signals - they are electronic Legos...only more complicated.

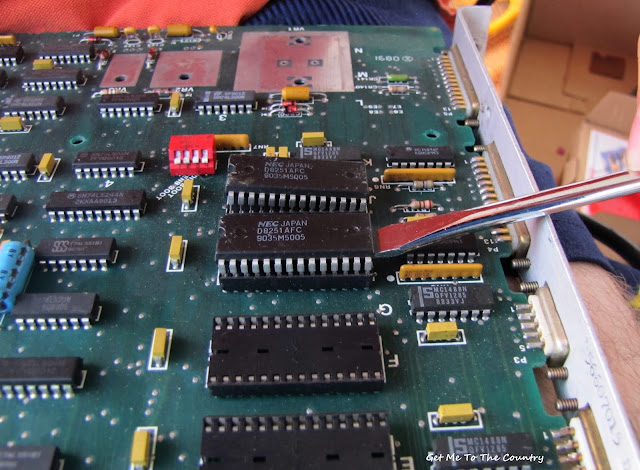

Using pliers, it is possible to carefully remove the component without damaging the good stuff.

Each component has the manufacturer's identifying marks and part numbers. The numbers can be googled for information. This one is a UVEPROM which was used as memory storage in an 80's style computer. Today it can be used in small computers. They can only be erased when ultraviolet light is shone into the clear window. The memory is not lost when power is interrupted. The data is also secure from being hacked or erased. To prevent accidental erasure, stickers are placed over the window. To erase the data for reuse, a small ultraviolet lamp pointed at the window will clear the data so it can be programmed again.

Some of the chips can be checked on an integrated circuit tester like the one below. It has a socket on the front so the circuit can be plugged in, identified and tested to see if it works.

The information is recorded then they are labeled and organized to be used in future projects.

Other treasures are discovered during the salvage process. This is a variable capacitor, not a flux capacitor, which came out of a harmonic distortion analyzer. It is something someone somewhere sometime long ago gave to Dustin. It can be used to make a homemade tuneable radio circuit. Brand new it would sell for quite a bit of money, too much to play with, but recycled out of a piece of trash, it becomes a priceless toy.

A degaussing coil was pried from an old CRT (cathode ray tube) computer monitor. Its purpose was to eliminate residual magnetization so the screen could work correctly. The coil operates on the same principle used in World War II by battleships to eliminate the magnetization of the hulls. It made them harder to be detected by naval mines. The mines could identify the changing magnetic fields created by the large iron ships.

It can also be used to degauss a dog.

As new construction projects and experiments are performed, Scooter offers instructions, advice, and encouragement.

Hey! Is that his childhood treasure box where he locked up his favorite toys to keep them away from his brothers? Is he throwing it away??? (Sniff, sniff) I suppose he is a little too old for a treasure box.

The recycling center appeared to be a popular place. The line was long and so was the wait. We got bored and thirsty.

So I found Dustin a can of beer. He said it was flat.

While waiting in line, I decided to search for excitement. Concealed between the piles of junk was a hidden path. Instead of bread crumbs, there were smashed aluminum cans pointing the way to a mystery. Where did it lead?

It led to the bottomless black hole where coke cans end up after they are thrown in the recycle bin. They are dumped in a hopper, shredded and the pieces are shot inside the back of a semi-truck trailer.

When the semi-trailer was full, it would be driven to another company to be smelted down.

As I continued on my treasure hunt, other surprises were discovered. Why would anyone want to throw away a genuine antique floppy disc drive? Shouldn't it belong in a museum? Millennials. They wouldn't recognize a priceless ancient artifact if they stepped on it.

No junkyard is ever complete without at least one junkyard dog. He was unimpressed by me and my camera and would not smile.

Finally! The man in the green truck ahead of us made it to the front of the line. He unloaded the iron from the bed of his truck and put it into the hopper.

We were next.

Our turn to unload!

First, the iron junk was pulled from the trunk and tossed into the hopper on the forklift to be weighed.

Everything else was carried to the weigh-in station near the large scale.

The men began quickly sorting the items by material type. They asked Dustin if he planned to return with more scrap later. He replied he would so they instructed him how best to categorize so he could earn the best price.

The scale was a huge metal plate surrounded by piles of stuff. Each category was weighed separately.

As items were weighed, the information was entered into the computer. Can't see the computer because of the messy desk? I added arrows so you can find it. Never, never, never again will I say my desk is messy.

Some items were too small and valuable to be weighed on the big scale. They were taken inside the office and weighed on a smaller scale. Can you find the office in this picture?

Not only does Dustin recycle junk, but he also recycles gloves. It's the reason he is wearing two different styles. This bag held discarded CPUs and integrated circuits. Some were broken, useless, outdated or not needed.

If they have gold plating on their connections it will bring more money so a sensitive scale was needed.

After being weighed, the items were tossed into boxes or piles.

Everything was totaled and a check was written to Dustin.

Was all the work worth it? ABSOLUTELY! He made $126.75 for a load of JUNK!

Hi Jeannie, You brought back memories. I used to assemble circuit boards many, many years ago. I was a solder pro. It is amazing what people throws out. Your son is smart to recycle. I hope he bought Scooter a bone!

ReplyDeleteHe did not buy him a bone. I just told him he need to do so.

DeleteSally - me as well! I was very proud of my solder certificate.

DeleteLarge scrapyards are adventurous and fantastic places. Mostly the dealers are headstrong

ReplyDeletecharacters. That is my opinion as I had been on these places several times when we sold

metal remains. It is quite important to sort all scraps: Copper, brass, aluminium, high-grade

steel and the rest of metal. Prices will vary according the metal stock exchange.

Christel

I forgot to mention that here in Germany you must show your identity card to the dealer when you

ReplyDeleteare selling any metal scrap. The tax office will check this (identity card number)as it might be

a source of income. If the sum you get is too big, you would be forced to pay taxes.

Dustin was required to show his driver's license and they took his fingerprints. He was not a licensed scrap dealer (who knew a license was required?) so we assume he fell under the tax minimum. We think the fingerprints were to make sure he had not stolen anything.

DeleteI think the government needs to mind its own business (protecting us from foreign invaders and coining money) and leave the small little guy alone.

Fascinating! My city recycles so I've never been to a junkyard, so this was fascinating! My takeaway: a) you have a smart son and b) Scooter did a great job!

ReplyDeleteI walked around stunned by the many piles of stuff. I fought the urge to pick up and start cleaning.

DeleteGood Grief! Who knew? I've never ever dismantled a circuit board, and would not know what things were if I did! My niece probably would, though, she works at Intel.

ReplyDeleteWe just have to put our recyclables in a bin and they haul it away for us. (Old tin cans, empty glass jars, cardboard, etc.) But, we do our own recycling of bottles and cans from drinks, as there is a deposit on them, and we can get quite a bit of money for them. 10c/can or bottle. We pay that when we buy drinks, so obviously the money comes when you find or are given some that someone dropped or doesn't want to bother with the recycle center with. My husband has taken many, many loads of scrap metal to sell over the years, especially when we lived on property. It seems to add up there.

You guys are amazing.

We took our nephew, Jake, camping for one last hurrah of the season. He did the junior ranger program. He was instructed to make something from recycled materials.With a little help, he chopped up my empty ziplock box and taped a picture on the page using the pieces of chopped up box. He probably would have loved to dismantle a circuit instead, but at least he won his patch.

The flat beer was hilarious!

He is a good sport when I bring out the camera and ask to take a silly picture. He knows which side his bread is buttered on and will always pose for food.

DeleteThis post was so informative for so many reasons. Your caution is well advised. Many, many years ago I worked for a company hand soldering components on PC boards. It was very complex work as we followed detailed procedures and one wrong component on a board could damage the whole (very valuable) board. We sat with our back to the wave solder machine - lead solder! There was a big ventilation hood but... We were tested monthly (!) for lead levels. Crazy to think of now. I then moved on to testing the boards and then QC. The next company I worked for I built the first of the HP "small" PCs (yes - it was HP - missed posting that). It crushes me when I see people just tossing electronic components into the trash - first of all, they are bad for the land fills and second they do have monetary value. So good on you Dustin!

ReplyDeleteThank you but I must say most of the information came from Dustin. He was dictating to me, then checking my spelling as he slowly explained it all to me. I am not very technical.

DeleteParis and Pueblo,

DeleteHi, and thank you for the encouragement! Getting components from old PC boards is more labor intensive than simply buying them new; however, if you sit down and run many boards through a solder pot, a small fortune in electronic components can be had for a few days' work. You're right: it truly is an unhappy sight when some electronic device is being thrown into a landfill when there are so many good components still inside. But it was nice to be able to send some arm-loads of junk to the recyclers instead of just tossing things into a landfill. Making a profit off of it was a pleasant surprise; I was only expecting about $50 for that carload of junk. Sure helps to make it worth the effort of sorting and hauling it!

I hope you never tested positive for lead poisoning, by the way.

-Dustin

My husband worked with boards with components in his working days. He has been gone for 5 years now, but he worked at Hughes Aircraft, in its day, in CA. He was an Tech. Some of his work is up in satellites. Dustin could get a great job. If he is not in college, he should go for engineering. I am new, and browsing thru your blog thru the prudent homemaker. Good luck with your garden!

ReplyDeleteDustin did get an Electrical Engineering degree but it took him almost three years of full-time job searching to finally land a good job. Now the company he is working at can't get chips (from China) for the factory and have begun laying off people. I fear, more companies will be closing until the supply chain is in better shape.

Delete